Description

FEATURES AND BENEFITS

- 100% Wireless, no easily damaged cables

- 700m/2300ft range allows operator to stand at

safe distance from test - Log data at speeds up to 200Hz

- Connects to any Straightpoint wireless load cell

- Automatically creates digitally signed pass or

fail certificate - Real time load v time graph display

- Free entry fields to note wind speed, sea states

etc.

APPLICATIONS

- Bollard pull tests

- Tug tests

- Crane Test (Water bags, block weights)

- Pad eye or fly point testing

- Crash barrier testing

- Lifting equipment testing – Slings, chains, wire rope, hooks

- Construction equipment testing – Shoring columns, acrow props and lintels

- Lifting and spreader beam testing

- Hydraulic cylinder load test

Numerous load testing applications worldwide require a load cell to verify the load applied. From crane testing using water bags to pad eye testing using hydraulic tools, the need to document test procedure and results has never been greater as users of lifting equipment call for more traceability and audit trails.

A proof test is a form of stress test to demonstrate the fitness of a load-bearing structure and is nominally a non-destructive test. Such a structure is often subjected to loads above that expected in normal use, demonstrating safety and design margin.

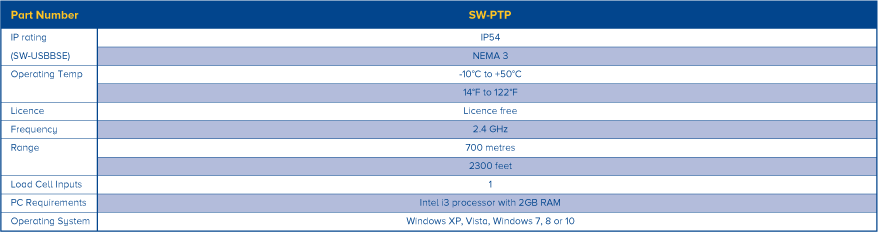

This demand has increased such that Straightpoint now offer a new software package designed to connect to any of their wireless load cells – ‘Prooftest plus’. This impressive package allows the test engineer to wirelessly, and at a safe distance, monitor a proof load test and automatically create a pass or fail certificate when testing is complete.

This report in PDF format may then be printed, emailed or uploaded to the cloud, resulting in a traceable document for both test engineer and end customer.execution.